FROM FIELD TO FABRIC

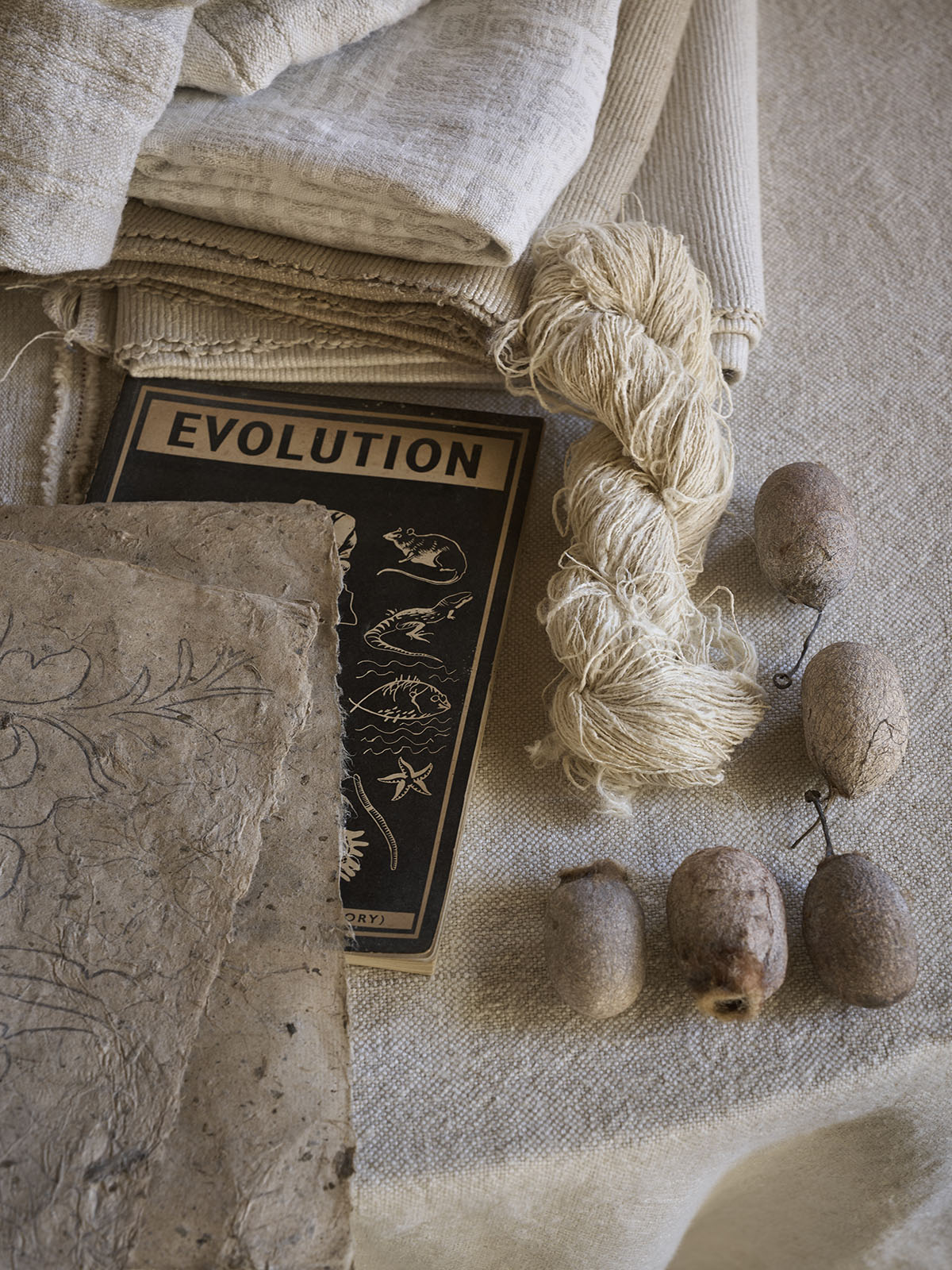

Bernie de Le Cuona and her team work exclusively with specialist mills to ensure we know the origins of every natural fibre used. Serious about sustainability, Bernie was the first to launch certified GOTS (Global Organic Textile Standard) 100% organic linen collections into the interiors market – the ultimate in sustainable luxury.

“Linen was where my journey with fabrics began. Its naturally sustainable qualities and my desire to create products that bring the health and wellbeing properties of nature into the home, make it a yarn I always return to when designing my collections.”

BERNIE DE LE CUONA

FOUNDER, CEO, AND CREATIVE DIRECTOR

FLAX

Flax is one of the oldest textiles known to man, dating back to the ancient Egyptians. It is a luxurious natural fibre that is also strong, durable, and versatile. Textures range from the raw and robust to the most refined.

Linen is made from the outer fibres of the flax plant. At de Le Cuona we use only the best quality Belgian and French flax fibres. The Flanders region is the best for flax cultivation and production because of its geographical location. The mild climate brought by the Gulf Stream and extremely rich soil allows the flax to grow to its highest, 80cm. The longer the fibre, the higher the quality of the linen. Using long fibres reduces the number of knots in the yarn and consequently a smoother fabric.

To ensure the highest quality, several batches of flax from different fields, areas, and years are mixed together by specialist spinners. The better the batches used for the mix, the higher the quality of linen fabric achieved. As a result of selecting flax from the longest fibres and mixing the highest quality batches, we achieve some of the most luxurious linen products available.

Using mills that work closely with artisans throughout the production process from the moment the seeds are planted to the finished linen fabric ensures quality and traceability. Many of our suppliers are part of the Masters of Linen and European Flax organisations and comply with REACH regulations.

HEMP

The first ever fabric known to man with a history stretching back 10,000 years.

Ancient Chinese dynasties mastered the use of hemp for clothing, rope, and even medicine. From here it began to spread West along the trade network of the ancient silk route.

Hemp is commonly regarded as the most sustainable natural fibre the earth has. It is very fast growing, producing up to three times as much fibre per acre as flax or cotton. Hemp fabric is made from the outer fibres of the stalk of the hemp plant which grows up to two metres tall and produces the longest and strongest of the plant fibres. However, there are several more steps required to process hemp ready for spinning into yarn compared to flax. Something that inevitably requires more time.

Hemp is a fibre not commonly used in interior textiles but one we have invested in and see growing in popularity as a beautifully sustainable choice.

ENVIRONMENTAL BENEFITS OF LINEN AND HEMP

Flax and hemp cultivation and production use very little energy and require no irrigation compared to other fibres like cotton, silk, wool, polyester, viscose, acrylic, or nylon. Unlike other agricultural crops they do not require chemicals or pesticides. Flax and hemp grown for de Le Cuona use only rainwater. River water is used during the linen fabric finishing process and then filtered before going back into the river.

Concerning the environmental impact of flax and hemp, a 2008 European Parliament evaluation report underlined that these crops clearly need less fertilizer and chemical pesticides than other crops. In addition, it states that both flax and hemp have positive effects on the agricultural ecosystems’ diversity and the landscape. In this context, growing these fibres offers a welcome ‘environmental pause’ in order to maintain soil quality, preserve landscapes and encourage bio-diversity.

Extract of the Advisory Commission’s Report to The European Parliament Brussels, May 2008

LIFESTYLE BENEFITS OF LINEN AND HEMP

Linen and hemp are both very durable and versatile natural fabrics, which makes them perfect for upholstery, curtains, and home accessories.

Both hemp and linen fabrics are kind to the skin, they are breathable, absorbent, and have antibacterial properties. They are resistant to moths, fungi, dust mites, mildew, and mould, and are non-allergenic. Both are effective insulators due to their hollow fibres making them cool in the summer and warm in winter. In their production, there is no plant waste because the whole plant is valued and can be used. The finished fabrics are biodegradable.

Lifestyle Benefits: Durable, Kind to the skin, Non Allergenic, Breathable, Absorbent, Antimicrobial properties, Resistant to moths, fungi, dust mites, mildew, and mold, Good insulator, Easy to clean.

WOOL, CASHMERE, LLAMA AND ALPACA

Wool, Cashmere, Llama, and Alpaca are natural fibres from the fleece of ruminant animals. Sheep, Llama and Alpaca are shorn for their wool once a year. Cashmere is combed from Cashmere goats each spring when the goats moult. These fibres are 100% natural, renewable, biodegradable, recyclable, and long-lasting. They provide warmth, softness, comfort, and beauty, are naturally fire resistant, while being remarkably strong and resilient and can be enjoyed for years and years.

WOOL

The earliest reliable discovery of wool textiles dates to the fourth millennium BCE. In Bronze Age Europe, wool production began to predominate over the processing of plant-based fibres.

There are more than 1,000 sheep breeds in the world. Breeds like the Merino produce fine wool while the Romney or Scottish Blackface produce thicker wool fibres. This range of fibres creates a diversity of fabrics from superfine cloths to thick robust textiles.

Our wool fabrics include 100% Merino wool and virgin wools to blends of wool and linen, or wool and silk. They range from the most robust textured upholstery fabrics to super-fine sheers and smart, tailored cloths.

LLAMA AND ALPACA

The domesticated llama is descended from the guanaco and the alpaca from the wild vicuna. All are native to the South American Andes.

The llama's wool is less commonly used than the alpaca. Alpaca fibre is known to be one of the softest, and finest in the world and is often compared to Cashmere.

There are two breeds of Alpaca: the Huacaya and the Suri. Huacayas have full, puffy fleeces with a crimp or crinkle that is found throughout their fleeces. Suri alpacas have silky, lustrous straight hair. Because the fleece from alpaca is so soft and does not contain any lanolin, it can be worn next to the skin, even by people with very sensitive skin.

The very softest alpaca fibre is called Baby Alpaca. It is the very finest fleece from the animal’s undercoat nearest the chest where the fibres are least exposed to the weather and dirt.

CASHMERE

Considered one of the softest and most luxurious animal fibres, cashmere is highly prized. Its name derives from a goat that is found across Kashmir in the Himalayas. To deal with the bitterly cold temperatures these goats develop two coats of hair: a thick, wiry topcoat and a super soft undercoat which is where cashmere comes from.

Each spring when the weather warms up the goats naturally moult and shed both the coarse and fine hairs. The goats are brushed gently to gather the under fleece. The fibres then undergo a selection process to keep only the longest and most delicate hairs. The fine cashmere fibre is six times finer than human hair and each goat only produces around 150gm of fibres. All these factors together are what makes cashmere a highly desirable luxury fabric.

SILK

Silk was one of the most important commodities traded in the ancient world. It has a captivating allure that has fascinated humanity for centuries. Its lustrous sheen, delicate texture, and luxurious feel make it a highly sought-after fibre, but belies its strength.

Silk fabric is hypoallergenic, perfect for those with sensitive skin or allergies. It’s naturally resistant to dust mites, mould, and other allergens. It also has exceptional moisture-wicking properties, and breathability, whilst providing excellent insulation keeping you cool in summer and warm in winter.

It is produced by the silkworm caterpillar which winds a long continuous filament around themselves to build their cocoons. Several silk filament strands are twisted together to form a silk yarn. The most common way to extract the silk filaments from the cocoons is to steam, boil, or dry them in the sun, killing the silk larvae inside. However, Peace silk is made without harming or killing the silkworms. It can be made from any type of silk. The silk cocoons are only harvested and processed after the moth has hatched from the cocoon. The moth secretes a liquid to dissolve a hole from which to hatch, breaking the long, continuous silk filaments into shorter staples. These must be spun together and create a thicker more textured yarn. It takes an extra ten days to wait for the larvae to mature into moths and hatch. What’s more Peace silk cocoons typically yield about a sixth of the fibre volume than conventional silk production. This extra process, the time required, and reduced yield are why Peace silk is more prized and more expensive.

Discover our Peace Silk Jungle Silk.

The most common form of silk is Mulberry Silk. It is a domesticated species that feeds on Mulberry leaves and accounts for the vast majority of the world’s silk production.

Tussah Silk, also known as wild silk, is harvested from the cocoons of wild silkworms in the forests of India and South Asia. Compared to cultivated silk the filament is uneven and spins into a yarn with more loft and texture. This creates fabrics with exceptional breathability in warm weather as well as insulation in cooler weather. It is also prized for its beautiful shades of cream, gold, and brown that give Tussah Silk such a distinctive look. Discover our Wild Silk Cushion.